MQL AND CRYOGENIC COOLING in machining processes

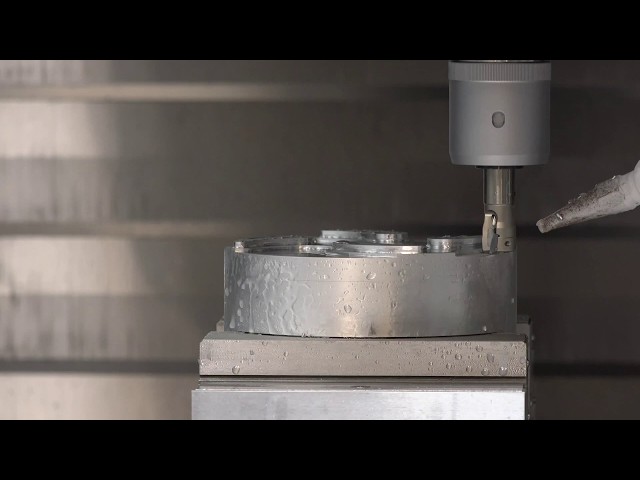

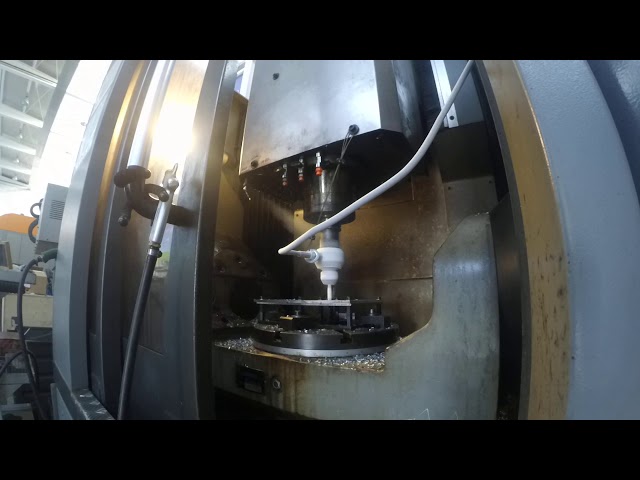

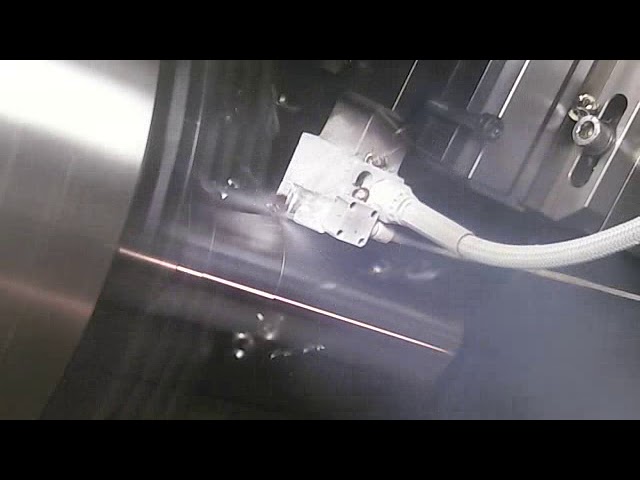

BeCold equipment technology combines Minimum Quantity Lubrication (MQL) with cooling provided by liquid CO2. The combination of these two systems results in excellent machining performance.

HRE Hidraulic offers different BeCold equipment series which can be adapted to different needs.

WHY USE cryogenic machining?

As a result of the industrial sector becoming highly competitive, reducing production costs together with the use of technologies with lower environmental impact are vital in the development of new applications.

BeCold equipment is fitted with an innovative system which combines Minimum Quality Lubrication (MQL) and CO2 cryogenic cooling to achieve performances equivalent or sometimes even better than traditional wet machining.

Removing or reducing conventional cutting fluids is paramount to succeed and the advantages offered by Cryogenic Machining make it the best option. The benefits are the following:

- cost SAVING.

- production BENEFITS

- environmental BENEFITS

MQL uses minimum quantities of biodegradable oils and CO2 captured from a primary process and later reused in a secondary industrial process as recycled gas, maintaining the inherent environmental production harmlessness of Cryogenic Machining.

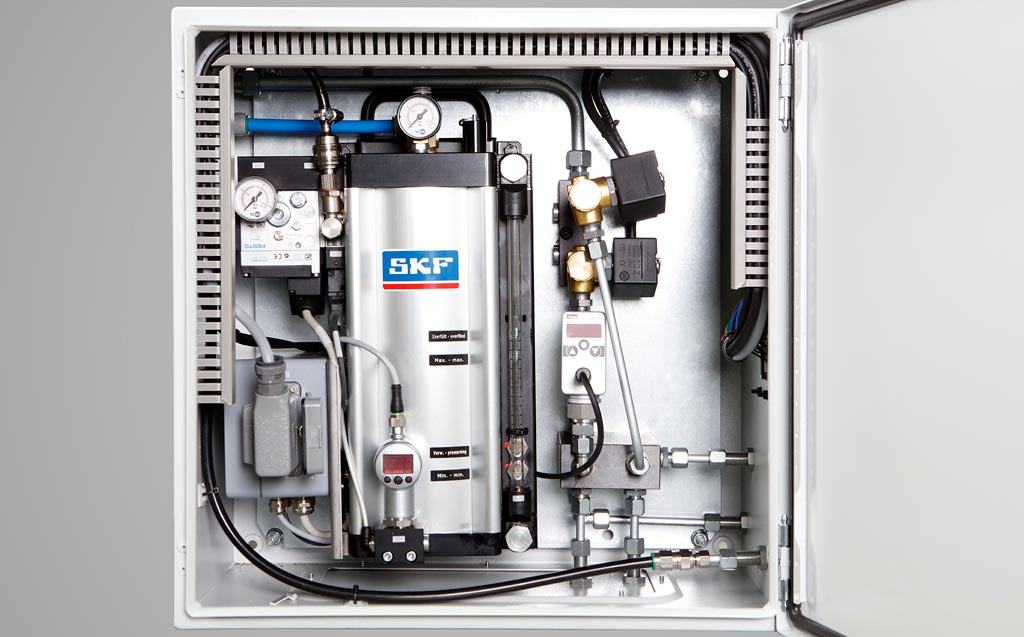

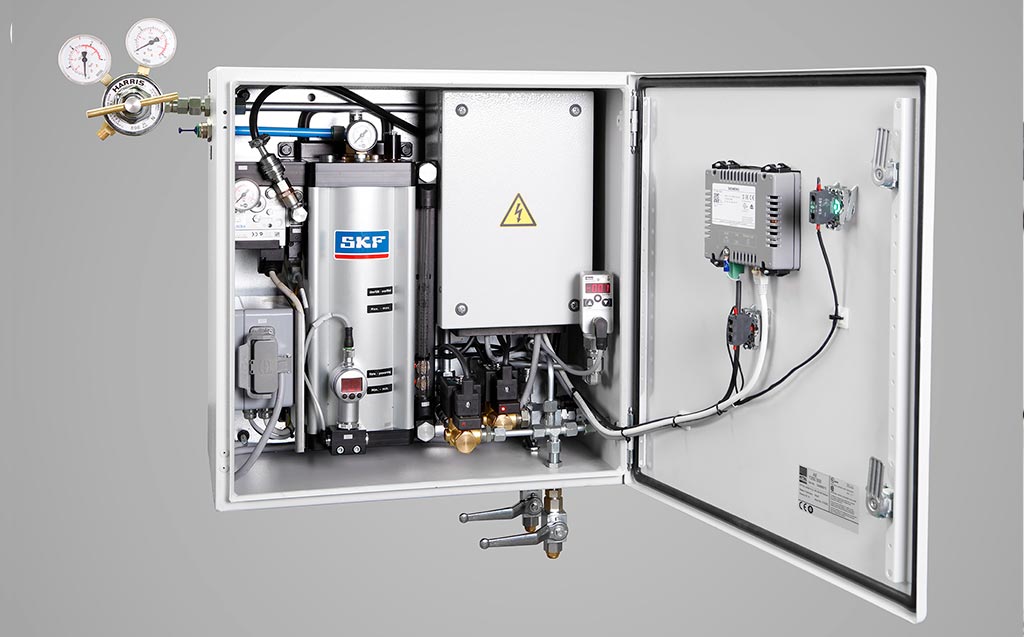

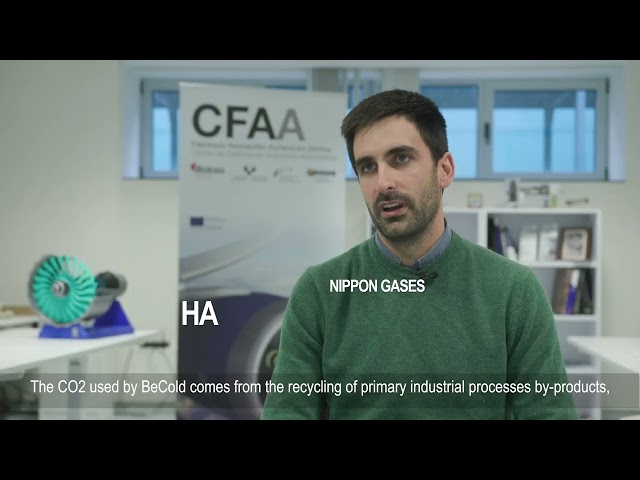

Suppliers

To achieve our goals, we combine our own knowledge with the highest quality components thanks to strategic alliances with world leaders.

Videos

Reference Articles

- In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis

- Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling

- CO2 cryogenic milling of Inconel 718: cutting forces and tool wear

- Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304

- Nozzle design for combined use of MQL and cryogenic gas in machining

- Cryogenic hard turning of ASP23 steel using carbon dioxide

- Internal cryolubrication approach for Inconel 718 milling

- Manufacturing of human knee by cryogenic machining: Walking towards cleaner processes

- Combination of high feed turning with cryogenic cooling on Haynes 263 and Inconel 718 superalloy

- A cleaner milling process replacing emulsion coolant by cryogenics CO2

- The Effects of Lubricooling Ecosustainable Techniques on Tool Wear in Carbon Steel Miling

- Alternative lubrication-cooling approaches for broaching medium-carbon steel: Machining performance and life cycle analysis