Market

OEM, a Multinational manufacturer of aviation components and assemblies.

Need

Reduction of tool change time while maintaining high repeatability and precision in both manual and automatic tool change. This time reduction is significant, mainly due to the batch diversity and size to be machined.

Solution

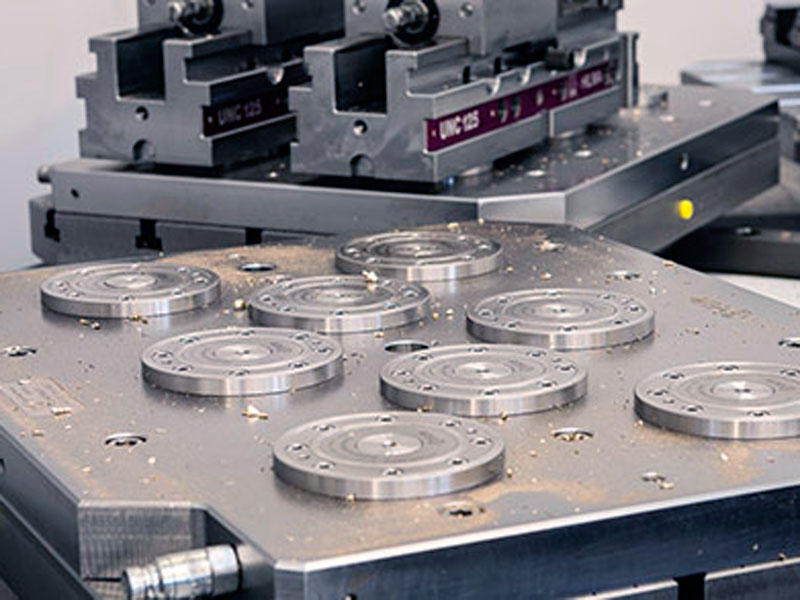

ZPS “Zero Point System” has its components on the pallet-holding tables and the pallets themselves. The new hydraulic decoupling system for the ZPS with status control and monitoring enables the cell to work autonomously, consisting of a FASTEMS type intelligent warehouse and 4 vertical machining centres.

Benefits

Savings of more than 50% in “chip-to-chip” time, the possibility of fully automatic operation and pallet positioning accuracy of less than 0.005 mm.