Market

Iron and steel industry – Manufacturer of large castings and forgings.

Need

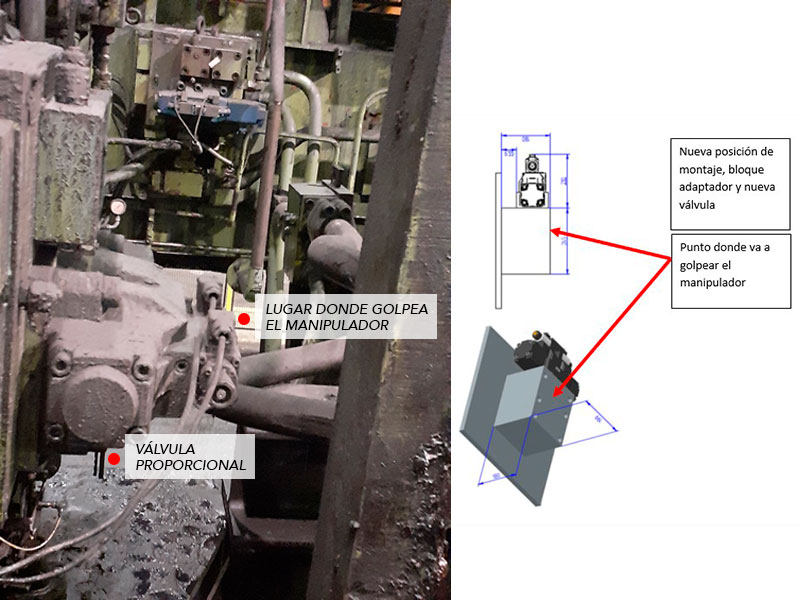

To increase speed and avoid direct impacts on a proportional valve of a competing brand installed on a huge manipulator for parts weighing several tonnes. The manipulator’s movement is controlled by a valve that must be installed close to a mobile hydraulic actuator which, due to its proximity, hits the valve and damages it within a few months.

Solution

The speed increase is achieved by replacing the TN25 size valve with a TN32 size valve with separate electronics. This means more volume and therefore also a higher risk of breakage due to the mobile manipulator being hit.

We designed a TN25/TN32 adapter block that also modifies the position of the valve and protects it from direct impacts.

Benefits

The new valve allows a higher flow rate and higher speed in the manipulator, therefore higher productivity for the customer.

The designed block and the new position achieved will avoid breakages due to direct impact, therefore direct savings in spare parts and machine stoppages.